Hemming for Press Brake Machine Manufacturers in Pune, Suppliers and wholesalers in Pune, Maharashtra

We are Raj Hightech Ventures Private Limited, we are the most trusted Hemming for Press Brake Machine manufacturers in Pune, suppliers, and wholesalers in Pune. Our offered hemming procedures can be mechanized using our CNC press brakes. As a result, there are fewer human errors and more accuracy and consistency along with lower labor costs.

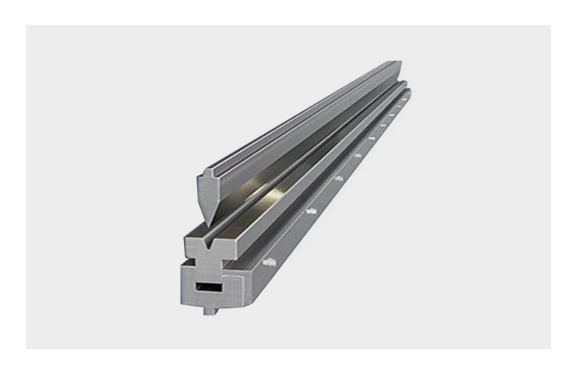

Hemming with a press brake is a metalworking method where the edge of a metal sheet is folded back onto itself. It is an essential stage in the manufacturing process of top-notch metal parts used in various industries like automotive, furniture, and appliance making.

Types of Hemming for Press Brake Machine:

As Hemming for Press Brake Machine manufacturers in Pune, we provide a variety of these products to ensure reliable performance. Here are some types of hemming for press brakes:

- Open Hemming: The process of open hemming entails folding the metal sheet's edge over itself to form a basic, open seam. This technique is frequently utilized for cosmetic reasons, offering a polished border without the need for complicated equipment. This method enables simpler access during the assembly and finishing stages.

- Closed Hemming: In this hemming, the sheet metal's edge is folded over and tightly secured, usually creating a completely enclosed seam. This kind of hemming offers enhanced strength and rigidity, making it ideal for situations where structural integrity is essential. Closed seams are often used in automotive components to prevent corrosion and enhance the component's overall longevity.

- Flanged Hemming: It is a technique that combines the advantages of open and closed hems by folding a section of the edge to form a flange. This method works well in situations where extra material is required for mounting or assembly needs. Flanged hems offer a stable hold for securing items and enhancing the product’s reliability.

- Offset Hemmig: It is the process of making a hem that is not in line with the material's edge. The hem is positioned differently to create a distinct design feature or to meet specific assembly requirements. This method can improve the appearance of a component while also serving practical functions, like creating space for other parts. Offset hems are commonly used in the automotive sector for components such as fenders and hoods.

Technical specifications of Hemming for Press Brake Machine:

as leading Hemming for Press Brake Machine Manufacturers in Pune, Suppliers and wholesalers in Pune, Maharashtra. Here is the attached table that provides an overview of key technical specifications of hemming for press brake:

| Specifications | Details |

|---|---|

| Product Type | Hemming |

| Material used | Stainless Steel, Aluminium, Copper |

| Finishing | Polished |

| Types | Open Hem, Closed Hem, Tear Drop Hem |

| Bend Radius | Typically, 0.5x to 1x material thickness |

| Thickness | 0.5 mm to 6 mm |

| Colour | Silver |

| Features | Corrosion Resistance |

| Packaging | Box |

| Brand | Raj Hightech |

| Edge Flatness Tolerance | ±0.1 mm to ±0.5 mm |

| Automation Capability | CNC integration for precision, repeatability, and reduced manual intervention |

| Usage | Automotive panels, aerospace parts, appliance housing, metal furniture |

Features of Hemming for Press Brake Machine:

As Hemming for press brake suppliers in Pune, our hemming offers numerous features, from safety and structural reinforcement to aesthetics and functionality. Here are some of these features:

- Edge Strengthening: Hemming enhances the durability and stiffness of the metal sheet’s edge, reducing the chances of it becoming deformed or bent.

- Smooth Edges for Safety: The hemming process folds the sharp edges of the sheet metal, making the final product safer to handle by eliminating sharp burrs

- Material Versatility: Hemming is versatile and can be used on different materials such as steel, aluminum, and stainless steel, with customized setups based on thickness and properties of the material.

- Minimal Tooling Requirement: The procedure is cost-effective due to its efficiency and the use of basic tools like standard hemming or flattening dies.

- Flexibility in Design: Pressing brake hemming can be used for a variety of designs, accommodating both simple and complex olds based on the needs of the part or desired edge appearance.

- Improved Aesthetics: Hemming improves the appearance of sheet metal by making it cleaner and more polished, especially for parts with visible edges in consumer products or decorative uses.

- Cost-Effective Edge Treatment: Hemming with a press brake is a more cost-effective option, particularly for large-scale production, in comparison to welding or other edge-finishing methods.

Applications of Hemming for Press Brake Machine:

As Hemming for press brake manufacturers in Pune, our offered hemming is a versatile sheet metal forming process with wide-ranging applications across various industries including:

- Automotive Industry: Used for creating smooth, reinforced edges on body panels, doors, and fenders, hemming enhances durability, fit, and safety in vehicles.

- Aerospace Industry: Hemming strengthens edges on thin metal components like wings and fuselage skins, providing lightweight yet durable reinforcement for aircraft parts.

- Appliance Manufacturing: Hemming is applied to metal housings and panels of appliances like washers, dryers, and refrigerators, offering a clean finish and ensuring safe, smooth edges.

- Furniture Manufacturing: Metal desks, filing cabinets, and outdoor furniture benefit from hemming to produce polished, safe edges, enhancing durability and preventing sharp edges.

Our industry has become one of the most popular Hemming for Press Brake Machine manufacturers in Pune, suppliers, and wholesalers in Pune, for providing top-grade products at affordable rates. We supply these Hemming’s in various specifications to satisfy the customer's requirements. This versatility enables them to address various design and functional requirements. Contact our well-known company and get an exciting offer!